Choose A Manufacturer

Overview of Manufacturing at Upper Yantic Falls

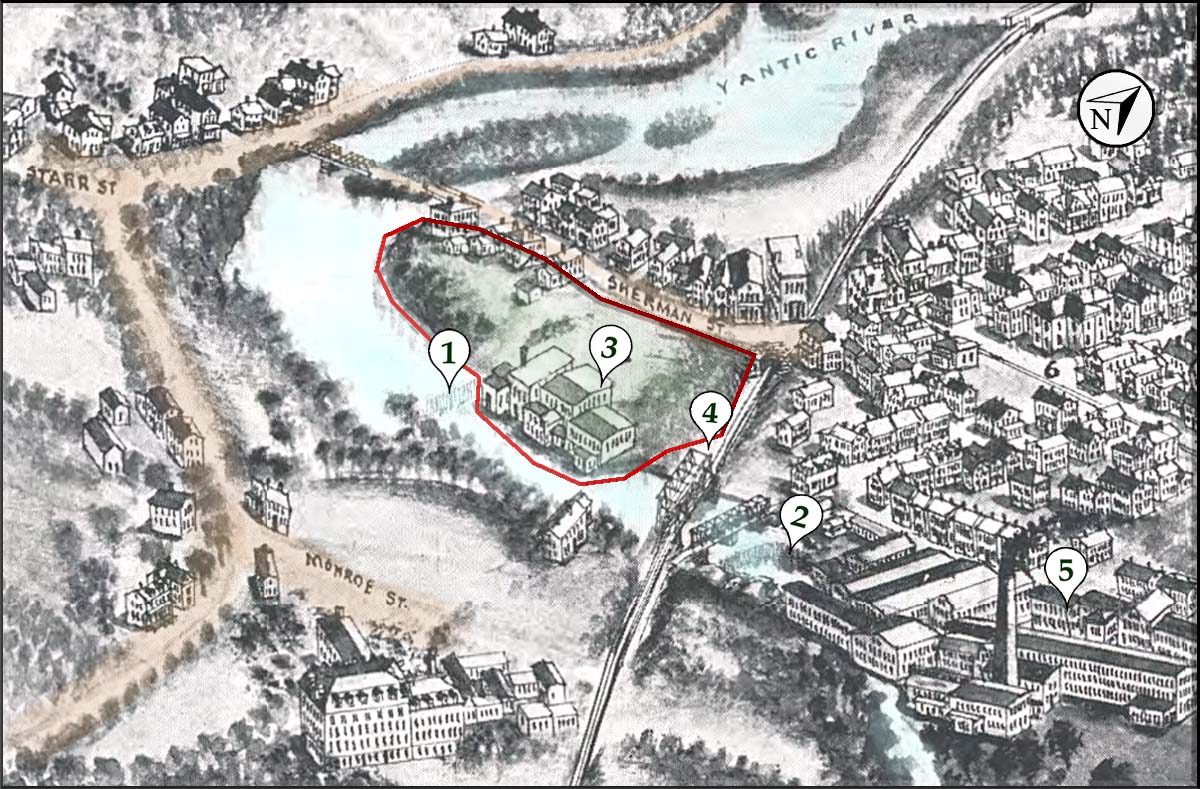

There are two sets of waterfalls on the Yantic river in Norwich. The subject of this placemark is the manufacturers who were located north (i.e. above) the lower falls, (as shown on the 1833 map below).

1833 Map of Upper Yantic Falls Area

Manufacturing at the upper falls area was begun soon after the first settlers arrived in Norwich. John Elderkin built a grist mill here that was used to grind corn. Later, in 1766, the site also became the location of Christopher Leffingwell’s paper mill, the first paper mill in Connecticut.

The upper falls site began to boom in the late 1860s when Charles A. Converse consolidated the Yantic River water rights and built the “Commonwealth Works”.

This group of manufacturers formed what could be described as a modern-day industrial park. There were gun makers, file makers, a braid mill, and others; all a part of the Commonwealth Works.

Strong’s Woolen mill is identified on this, 1833 map, however not much is known about this mill.

The location of Russel Hubbard’s 1st Paper Mill on this 1833 map. This site was previously the location of Christopher Leffingwell’s paper mill.

Today, most of the land designated as “Upper Falls Area” in the map above is owned by the town of Norwich and is called the Upper Heritage Park.

Acknowledgements

“A Modern History of New London County Connecticut, Vol. 1,” 1922, p 153, by Benjamin Tinkham Marshall

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” pp 611-614, by Frances Manwaring Caulkins

“A Sketch of Norwich from Actual Survey,” 1833, by William Lester, (Map annotations by IconicNorwich.org)

1660-166? John Elderkin Gristmill

Even before the original 35 proprietors moved from Saybrook to Norwich they contracted with John Elderkin to build a gristmill at their future settlement. Most of the proprietors were farmers and they knew that a mill would be needed to grind their grain. From the ground grains they could make bread, a staple part of their diet.

The earliest town act of which any record has been found is dated December 11, 1660. It was a renewal of a contract to between the “Town of Moheagan” and John Elderkin to build a grist mill. In the contract Elderkin agreed to pay a fee if the mill at Norwich was not completed by November 1, 1661. The contract also gave him the privilege of operating the mill for a term of years as a kind of monopoly of the business.

Although the terms “gristmill” or “corn mill” can refer to any mill that grinds grain. The terms were used historically for a local mill where farmers brought their own grain and received back ground meal or flour.

The mill at Norwich was first erected at No-man’s Acre, above Yantic Falls, but was soon removed to a site below the Falls. The mill in the photo shows how Elderkin’s mill may have looked.

In 1922, Info Source 1 describes the mill site as :

“Today the spring still gushes forth the pure water which made it noteworthy in the olden time. Elderkin’s Mill, “the valley near the mill in which the Spring is”, and “the deep valley that goeth down to Goodman Elderkin’s house,” and the “island before his house at the Mill Falls” are all mentioned in early deeds.”

The mill most likely used a vertically mounted water wheel which was powered by water from the Yantic River. The wheel would turn an axle, which in turn turned a millstone, which ground the grain.

Info Sources 1 & 2 contain much more information about John Elderkin.

Acknowledgements

“A Modern History of New London County Connecticut, Vol. 2,” 1922, pp 570-571, by Benjamin Tinkham Marshall

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” pp 72-73, by Frances Manwaring Caulkins

1766-1772 Christopher Leffingwell Paper Mill

In 1766 John Bliss, the great-grandson of Thomas Bliss Jr., built the first paper mill in Connecticut for Christopher Leffingwell . Bliss was a builder who had also learned the skill of making paper while working in a large paper factory in Philadelphia. Leffingwell’s mill was erected in the Upper Falls.

In the short period that the mill was open, 1766-1772, the 10-12 employees, produced paper for wrapping, writing, printing, sheathing and it was able to turn out 1300 reams per year.

In the years just prior to the Revolution paper was vital for disseminating information and influencing public opinion. Obtaining paper was a major problem for colonial printers. All paper was imported from England until 1691. In that year, the first paper in the American colonies was produced in a Pennsylvania mill. Paper mills slowly sprang up in each of the colonies. In 1766 Connecticut became the seventh colony to have a paper mill when Christopher Leffingwell opened his in Norwich. In December 1766, the Connecticut Gazette, Connecticut’s earliest known newspaper, was printed on paper from Leffingwell’s paper mill.

Interior of an 18th Century Paper Mill

*Place cursor over map to enlarge

Making Paper in the 18th Century

The first stage in the papermaking process was to select the material from which the paper would be made. In the eighteenth century, this would typically have been cotton or linen rags.

The next step was to break it down and make it into a pulp. In the eighteenth century, a beating engine, or a Hollander beater, was typically used to tear up the material, creating a wet pulp by circulating rags around a large tub with a cylinder fitted with cutting bars.The liquid pulp mixture would then be transferred to a container.

The ‘vatman’ would have stood over this container and dipped a mold into the solution at a near-perpendicular angle. Turning the mold face upwards in the solution before lifting it out horizontally. He would have then pulled out the mold and found an even covering of macerated fibers assembled across its surface. It is these fibers that would later form the finished sheet of paper.

This sidebar discusses the typical paper-making process in the 18th century. It is unknown if this was the exact process used in Christopher Leffingwell’s paper mill.

The government subsidized Christopher Leffingwell’s mill for the first three years of its operation. The mill was not financially successful at the start and only proceeded to get worse. It required government aid to keep it running, which eventually ran out, causing the mill to close.

In 1811, several years after Leffingwell’s mill closed and soon after Leffingwell’s death, his estate sold the old paper mill to Russell Hubbard and two other investors. The building became the site of the Russell Hubbard’s first paper mill.

Acknowledgements

“Old Houses of the Ancient Town of Norwich, 1600-1800,” 1895, pp 33-34, by Mary Elizabeth Perkins

“History of Connecticut Newspapers,” Connecticut State Library

“Paper and Provisions: Christopher Leffingwell and Connecticut During the American Revolution,” by Amirah Neely

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Leffingwell Paper Mill” or “Making Paper in the 18th Century” in the SEARCH box.

1811-1857 Russell Hubbard's First Paper Mill

1833 Map of the Upper Falls Area

In 1811 Russell Hubbard and two other investors purchased the old Christopher Leffingwell paper mill from Leffingwell’s estate.

The location of Russell Hubbard’s paper mill is shown on this 1833 map.

In 1815, Russell purchased the interests of his partners and became the sole proprietor of the mill. He also published the local newspaper, The Courier, from 1806-1822. It is likely that paper produced in this mill was used to print his newspaper.

Later, in 1837, Russell joined with his younger brother, Amos, and formed the R. & A.H. Hubbard partnership. Together, they owned and operated two paper mills at the Falls (this one in the Upper Falls area and another one in the Lower Falls area). This partnership lasted from 1837 to 1857, when Russell died.

In 1860, Amos sold both of their company’s paper mills to the Falls Company and relocated the business to Greeneville.

Click HEREto learn more about the Hubbard’s paper-making business in the Lower Falls.

Acknowledgements

“Genealogy and Biographical Record of New London County Connecticut,” 1905, pp 19-20, by J.H. Beers

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” p 613, by Frances Manwaring Caulkins

“A Sketch of Norwich from Actual Survey,” 1833, by William Lester

The complete list of sources may be found by clicking the “Bibliography” button, and, then entering “Hubbard” in the SEARCH box.

Commonwealth Works Site

The Commonwealth Works Site is an historic industrial site located near Yantic Falls on the Yantic River in Norwich. It was the location of a multi-functional industrial facility developed in the mid-19th century, with an industrial history dating back to the 18th century.

This Iconic Norwich placement only addresses the business enterprises directly associated with the Commonwealth Works business operating at the site after 1864. Previous to, and after, this period in time there were numerous other enterprises that are not addressed here.

In 1865 Charles A. Converse consolidated water rights at Yantic Falls and built a large brick building, the “Commonwealth Works”. The facility housed a number of different water-powered enterprises. They included the gun factory of Bacon Manufacturing Company, Hopkins & Allen Manufacturing Company, a braid mill, a cork-cutting factory, Norwich File Works, a Dye Works and several others.

The site was added to the National Register of Historic Places in 1998.

Annotations added by IconicNorwich.org

NOTABLE PLACES

- Upper Yantic Falls: All the enterprises located at the Commonwealth Works Site relied on the energy produced from the fall of water at Yantic Falls.

- Lower Yantic Falls: The scene of Indian Leap.

- Commonwealth Works Site: The site was equivalent to a modern-day industrial park. Several water-powered industries were clustered here. As shown in the maps above, the Commonwealth Works Site was located just below the Upper Falls and above the Lower Falls.

- New London Northern Railroad: From 1861-1872, the New London Northern Railroad operated train service from New London, through Norwich, to Brattleboro, Vermont. The goods manufactured at the Commonwealth Works site had easy access to markets via this railroad.

- Falls Company Cotton Mill: A large cotton factory located below the Lower Falls are. The Falls Company Cotton Mill was not a component of the Commonwealth Works site. It is highlighted in the map as a reference point.

ENTERPRISES

- Bacon Manufacturing Company (1858-1868): The Bacon Manufacturing Company made revolvers and single-shot pistols. The company had approximately 10 employees and operated in two rooms in the Auger Mill building. Charles A. Converse, the landlord of the building, took control of Bacon Mfg. Co. in October 1863, due to a disagreement between him and Thomas Bacon, the founder of the Bacon Mfg. Co. In 1868, Converse and several others formed Hopkins & Allen from the remnants of Bacon Mfg. Co.

- Hopkins & Allen Manufacturing Company (1868-1916): Hopkins & Allen was a successful arms manufacturer for 48 years. They began their operation at the Commonwealth Works site in 1868 and then moved to a larger facility in downtown Norwich in 1878. Map Source 1 shows the exact location of Hopkins & Allen.

- Norwich Falls Pistol Company (1882-1887): They produced several lines of inexpensive revolvers at the Falls.

- Cork-cutting Factory: The cork-cutting factory was operated by J. H. Adams and James E. Learned. The cork-cutting business was one of the specialties in Norwich in the 1860s. They used a cork-cutting machine invented and patented by William R. Crocker of Norwich in 1855. The machine produced from twenty to thirty finished corks per minute, producing them in better condition than those made by hand. Click HERE to learn more.

- Braid Mill (prior to 1869): A so-called braid mill, or worsted manufacturer, was operated by James Townsend. There was a fire in the building, owned by Charles A. Converse, on January 20, 1869. The fire resulted in considerable damage. Click HERE to learn more.

- Norwich File Works: The 1870 Stedman’s Directory lists the Norwich File Works as being located at Commonwealth Mills. Click HERE to see the listing.

- Chelsea File Works (1912): This location of this file cutting enterprise is shown on the Aero View map of Norwich, Connecticut, 1912, by Hughes & Baily. The establishment is identified in the legend as Chelsea File Works. Click HERE to view the map.

- Dye Works: The 1870 Stedman’s Directory of Norwich lists David and Samuel Whitely as operating a dye works at “Yantic 1”. Click HERE to see the listing.

- Grist Mill: A photo of the grist mill is available at Info Source 1

- Other Enterprises: Several other enterprises have been identified in Info Source 1 as being associated with Commonwealth Works. They include a saw mill, a nail manufacturer, a flour mill, and a foundry.

Acknowledgements

“The Mysterious “Colonel Charles Augustus Converse,” The Muse Newsletter, Summer 2007, by Vivian F. Zoë

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” p 614, by Frances Manwaring Caulkins

“City of Norwich, Conn. 1876,” by O. H. Baily & Company

“Aero View of Norwich, Connecticut 1912,” by Hughes & Baily

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Commonwealth Works” in the SEARCH box.