Choose a Manufacturer

1845-1881 Sidney Risley Pottery

1848-1897 C.B. Rogers & Company

1889-1938 Norwich Cutlery Company

1893-1927 Uncas Paper Mill

1894-1930 Ulmer Leather Company

1916-1921 Norwich Woolen Co.-Thamesville

1923-1969 Werman's Shoe Factory

1930-1972 Thames Belting Company

Overview of Manufacturing at Thamesville

1912 Map Showing Location of Several Thamesville Mfg’s

*Place cursor over maps to magnify

1892 Map Showing Location of C.B. Rogers & Co.

The development of manufacturing enterprises in Norwich grew over time. The beginnings of manufacturing in Thamesville was a pottery operated by Sidney Risley from 1845 to 1875. His first shop was located near the west bank of the Thames River, only a few blocks south of the present-day Norwich Police Station.

Thamesville was one of the last large-scale manufacturing sites to develop in Norwich. Two of the key components needed for efficient manufacturing were the availability of power and ability to transport both raw materials into a plant and export the finished goods. Purely based upon Norwich’s geography and native resources located at the Yantic Falls and Greeneville areas, these sites naturally developed first.

Soon after the New London Willimantic & Palmer Railroad was built in 1848, the Thamesville manufacturing site began to blossom at the C.B. Rogers & Company facility. Upon inspection of the map above, it can be noted that both the railroad, then operated by the Central Vermont Railroad, and the Thames river were available for transporting goods.

Also, the very important Thamesville power station was available to the manufacturers. Greeneville received the first large electric light light station in 1890, and as seen on the map above, Thamesville had a substantial power station by 1912.

All the manufacturers discussed in this section were located adjacent to both the railroad and the Thames river, giving them efficient means to make and transport their goods.

Acknowledgements

“Aero View of Norwich, Connecticut 1912”, by Hughes & Bailey

1892 Sanborn-Perris Fire Insurance Map of Norwich

“The Gas and Electric Early History”, by Ray Bourque

1845-1881 Sidney Risley Pottery

In 1845 Sidney Risley established a small pottery in Thamesville near the bank of the Thames river, behind present-day 76 West Thames Street. Sometime before September 1845, Risley moved his pottery to 4 Cove Street at Chelsea Landing. The advertisement shown below appeared in the 1857 Norwich Directory.

Sidney Risley, No. 4 Cove St. Manufacturer of Stone Ware in Every Variety

The Trade Supplied With All Kinds of Stone Ware, At the Lowest Market Prices

All Orders Thankfully Received and Promptly Attended To

Other advertised items included money safes for children and a cider bottle in the shape of a hollow ring made to be carried on the arm of a mower in the field.

Pitcher by Sidney Risley

This is a photo of one of pitchers that was created at Risley’s pottery.

Wood for the kiln was delivered by boat or a team of horses. Everyone in that section of the town knew when the fires were going at the pottery, for the dense black smoke from the three-foot sticks filled the sky for a space of from 36 to 50 hours, according to the particular kind of work being done. The clay used in the manufacture of the wares is said to have been brought from New Jersey and Long Island in schooners which anchored in the river nearby.

The wares of the Risley pottery, were loaded in wagons and peddled throughout all the eastern part of Connecticut using two one-horse wagons. One of Risley’s drivers, Alvin T. Davis, had his pottery wagon hitched with a fine pair of Newfoundland dogs ahead of the horses.

Crock by Sidney Risley

Risley’s son, George L. Risley, joined the business in 1865. He continued to run the pottery after his father’s death in 1875. George operated the pottery works until his own tragic death on Christmas eve of 1881. he went to the pottery to light the fires under an upright boiler, which blew up, and, going through the roof of the building, landed in the cove about 120 feet away. It is said that the force of the explosion was so great that the 1500-pound boiler passed completely over a fifty-foot elm tree at the rear of the pottery. Mr. Risley was so badly injured that he died that evening. An account of the accident appears in the January 1882 issue of the Scientific American magazine.

Benjamin C. Chace reopened the pottery about a year after George’s death, under the name of the Norwich Pottery Works. In 1885 he was succeeded by George B. Chamberlain, who continued it for about two years.

Acknowledgements

“A Modern History of New London County Connecticut, Vol. 2”, (1922), pp 550-551

“From Kiln to Collection : Norwich Pottery and Its Makers”, by Sierra Dixon

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Sidney Risley” in the SEARCH box.

1848-1897 C.B. Rogers & Company

Caleb B. Rogers got his start in the woodworking machinery business working for the J.A. Fay & Company in Keene, New Hampshire. After several years of cooperation in Keene, Caleb Rogers and J.A. Fay partnered to build a second factory on the west side of Norwich. The factory was located near the present-day Norwich Police Department.

The new facility was needed to produce the company’s newly designed sash sticking machine. This machine met with an unprecedented demand. Over a three year period period the company sold one machine per day, on the average.

*Place cursor over photo to magnify

C.B. Rogers & Company was a large manufacturer of wood-working machinery. The Norwich factory first started in 1848 on a small scale, but gradually increased. By 1863 it was incorporated as a joint stock company.

Their machinery found sales not only in the United States, but was also in South America, Mexico, New Zealand, Australia and various European countries.

Over the years their machinery was exhibited all over the world and won more than 100 gold, silver or bronze medals.

In 1873 the company their machines were shown at the prestigious Vienna International Exhibition, in Vienna. They exhibited a variety of machinery including a double-surface and matching machine, a four-sided molding machine, a four-sided molding machine, a double head and cape tenoning machine, a sash sticking machine, a hub mortising machine, a saw arbor and a grooving saw arbor.

The factory, including the foundry, covered nearly three acres of ground. The manufactory surrounded three sides of a quadrangle, and consisted of the main building, 125×45 feet, four stories, with blacksmith shop, 30×25 feet, attached; a wing, 65×40 feet, four stories; and a second wing, 50×20 feet, three stories. The fourth side was occupied by a storehouse, 100×30 feet, three stories, for lumber and coal. The factory had about 40,000 feet of floor space.

The engraving shown above is a depiction of the interior of the C.B. Rogers & Company factory in Thamesville

The machine shown above is a three-side, 24 inch planer. It was manufactured by Rogers in 1872

They prided themselves on using the most up-to-date modern manufacturing techniques. They employed 18 patents from Norwich-based inventors C.B. Rogers, Frank Douglas, Dalphon L. Gibbs, George W. Gould, Lyman Gould, and Byron Boardman. In an 1881 advertisement they announced that the company used the “Most Improved Patterns,” such as Norwich’s Byron Boardman’s patent for barbed blind staples.

In 1888 the company employed 125 people at an average wage of $560 per year ($14,700 in today’s dollars). C. B. Rogers supervised the entire Thamesville plant, and upon the death of Fay in 1854, Fay’s interests in the company were transferred to Rogers.

C.B. Rogers died an untimely death in 1871. He was one of a dozen people who died aboard the steamship “City of New London”. The ship caught fire and sank only 3½ miles from the Chelsea Harbor port. To learn more about the accident, CLICK HERE

After his death the company continued to operate successfully under the guidance of Lyman Gould. In 1897 C. B. Rogers & Co. merged with ten others to form the American Wood Working Machine Company.

Acknowledgements

“Norwich Connecticut: Its Importance as a Business and Manufacturing Centre and as a Place of Residence”, 1888, page 26, by the Norwich Board of Trade

VintageMachinery.com

VintageMachinery.com

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Rogers” in the SEARCH box.

by the William Rogers Mfg Company

1889-1938 Norwich Cutlery Company

For many years the Norwich Cutlery Works was a branch of the International Silver Company. They made steel blanks in the shape of knives, forks, carvers, etc. The plant was located on the Thames river, as shown at the top of this webpage, employing about 100 workers.

The firm began production in 1889, and its entire output of steel table cutlery blanks was purchased by the William Rogers Manufacturing Company for plating and finishing in Hartford. The blanks were coated with silver or gold.

Norwich Cutlery initially employed 50 hands and was capable of turning out 150 dozen knives per day. The company operated in this manner for ten years before being acquired by the International Silver Company in 1899.

The photo on the left illustrates a typical finished product that the William Rogers Manufacturing Company (based in Hartford) sold at retail. The Norwich Cutlery Co. made “blanks” that were used by the Rogers Company to make plated silverware similar to the ones shown here.

The International Silver Company was organized under the laws of the State of New Jersey on November 19, 1898. Essentially a holding company, the firm acquired control of 17 of the most significant manufacturers of silver products in the United States and Canada within its first year of existence.

The International Silver Company grew to become the largest producer of silver products in the United States and by the early 1900s had expanded into a massive industrial concern valued at $20,000,000.

International Silver made numerous improvements to the Norwich plant and occupied it into the 1930s, by which time employment there had risen to 140 hands. Damage resultant of the 1938 Hurricane, however, was deemed not worth repairing and International Silver vacated the plant at that time.

Acknowledgements

ConnecticutMills.org

“Picturesque and Industrial Eastern Connecticut”, 1914, page 8, by the Eastern Connecticut Development Committee

“William Rogers Mfg Co. “Wedding Bells” Pattern”, Quora.com

1893-1927 Uncas Paper Mill

In 1893 the Chelsea Paper Company was reorganized as the Uncas Paper Company. Soon after the reorganization, the new mill, shown above, was built in Thamesville. The company became a a division of the American Strawboard Company. This mill, like the Chelsea Paper Mill in Greenville, was also one of the largest paper mills in the country. However, the Uncas Paper Mill focused on producing paper board products and paper boxes rather than paper used for print, produced by the Chelsea mill. Uncas mill products were sold around the world and their plant operated around the clock utilizing two 12-hour shifts to keep up with demand.

As a part of Norwich’s 250th Anniversary in 1909, the Uncas Paper Company entered a handsome float which attracted much attention. The float featured a canoe on a sixteen-foot carriage, with material about it representing water. Elevated length-wise on the float was a roll of news board four feet in diameter. At each corner was a roll of paper, the product of the mill, and on each side of the float were four foot circles, through which could be seen Indians paddling the canoe. The rings were decorated with roses and foreign flags, representing export trade, and at the front and back were large American flags. The float was drawn by four horses and bore the sign, Uncas Paper Division, American Strawboard Co.

The Uncas Paper Company was forced out of business by lawsuits in 1927.

Acknowledgements

“The Celebration of the Two Hundred and Fiftieth Anniversary of the Settlement of the Town of Norwich, Ct and the Incorporation of the City, the One Hundred and Twenty-Fifth, July 4-6, 1909”, by William C. Gilman, published in 1912, page 166

“The Norwich Evening Record”, by Cleworth & Pullen, 1894, page 61

Public Domain

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Uncas Paper” in the SEARCH box.

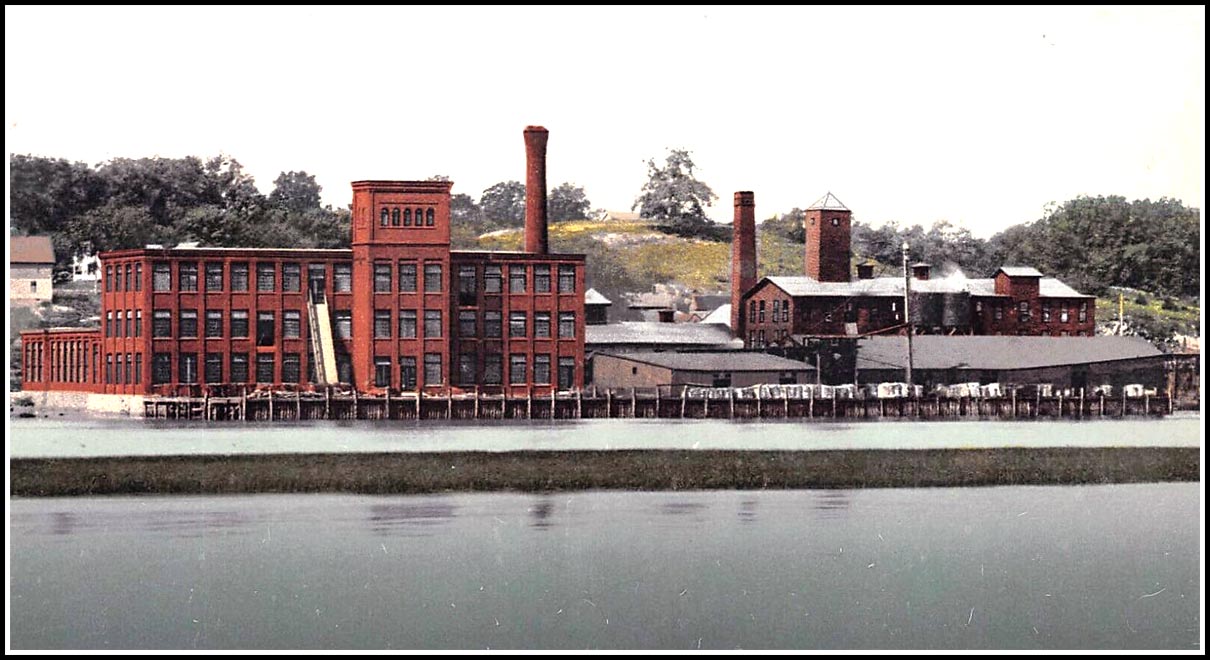

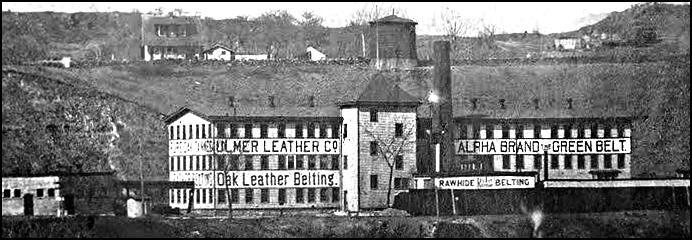

1894-1930 Ulmer Leather Company

Frank Ulmer and his son Henry formed the Ulmer Leather Company, located at the end of Forest Street in Norwich in 1894. (Info Source 1).

It was a tannery and a manufacturer of commercial leather belting, rawhide lace, hydraulic leather, and pump valve leather.

This 1912 map shows the location of their facility

*Place cursor over images to magnify

This letter was sent to the Farr Alpaca Co., (1874-1942) in Holyoke, Massachusetts on 12/11/1895 via American Express. The document was a cover letter for the delivery of an 18″x18″ piece of hydraulic backing. It is earliest known correspondence issued from the Ulmer Leather Company.

By the beginning of the 20th century the Farr Alpaca Co. had the largest alpaca woolen mill in the world and was a dominant producer in its industry.

*Place cursor over images to magnify

This 1901 invoice provides more info about the company. It shows that the company, in addition to leather belting, rawhide lace, and pump valve leather, they also produced “Dynamo & Silk Machinery Belts.”

The invoice clearly shows Frank and Henry Ulmer’s names and provides and shows the logo for their “Sachem Extra Grade” leather.

*Place cursor over images to magnify

This advertisement published in the 1909 Norwich Board of Trade book shows that the company sold “Sachem” brand Oak Bark Tanned Leather Belting. The ad states: “The leather could withstand heat, moisture, gases and acid fumes better than any belt made.” (Info Source 2)

The ad shows that the company also produced and sold waterproof cement.

*Place cursor over images to magnify

*Place cursor over images to magnify

As a part of Norwich’s 250th Jubilee, the Ulmer Leather Co. entered the float picture in this postcard.

In 1930 the company was sold to several Ulmer employees. They formed and began production as the Thames Belting Company.

Franz (Frank) Ulmer was born on 6 March 1845 in Darmstadt, Germany. He married Elenore Frickmann on 19 April 1868, in Norwich. They were the parents of 5 children Henry (who took over the tannery business upon Frank’s death), Catherine, George, Joanna, and Eleonore.

Frank and his family lived in Norwich for about 20 years. He died on 23 May 1903, at the age of 58. His gravesite is in the Yantic Cemetery. Info Source 1 provides a biography of his life.

Acknowledgements

“A Modern History of New London County Connecticut Volume III,” (1922), by Benjamin Marshall Tinkham

“1659-1909 Norwich Connecticut,” (1909), by the Norwich Board of Trade Quarterly

“Ulmer Leather Company Letter to Farr Alpaca Company,” (12/11/1895)

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Ulmer” in the SEARCH box.

1916-1921 Norwich Woolen Co. - Thamesville

The first Norwich Woolen Mill was established in 1827 and operated in the present-day Yantic neighborhood of Norwich. The enterprise was incorporated as the Norwich Woolen Company circa 1877. They manufactured flannel, a high-quality carriage cloth. By 1900 the firm had transitioned into the production of woolen and worsted fabrics for suits and outerwear. At that time the company employed approximately 125 employees turning out 250,000 pounds of product per year.

In 1916 the company expanded its production when it built a new, more modern plant in the Thamesville area of Norwich. The Thamesville mill was conveniently located adjacent to both the Thames river and the Central Vermont Railway, had the ability to easily transport raw materials and finished products both into and out of the mill. Refer to the map located at the top of this webpage.

1921-1955 American Woolen Co. - Thamesville

In 1921, the mills owned by the Norwich Woolen Company in both Thamesville and Yantic were acquired by the American Woolen Company, a large conglomerate of New England textile mills originally established in 1899. They idled the Yantic mill after consolidating all production at the Thamesville facility. At the time of the transaction, the American Woolen Company was the largest manufacturer of woolen and worsted fabrics in the world and maintained 58 mills in eight states.

In 1921 the Norwich mills employed around 500 workers and were equipped with 24 sets of carding machines and 170 broad looms. These were purchased along with the respective plants for a sum of $570,000 ($1.4 million in today’s dollars). The American Woolen Company rapidly increased production and by the end of 1921 the Thamesville mill alone boasted 650 employees, 21 sets of cards, 88 looms, 7056 spindles, and 32 knitting machines.

Employment dropped below 300 by the late-1930s, however, American Woolen continued to maintain the Thamesville plant into the 1950s. By 1954, competition with Southern textile mills forced the company to close the Norwich factory and the remaining 150 employees were laid off.

The plant was in turn acquired by Sawyer Displays, Inc., a Putnam, Connecticut based manufacturer of display and advertising products. Sawyer Displays occupied the Thamesville factory into the late-20th century.

Acknowledgements

ConnecticutMills.org

“Special Acts and Resolutions of the State of Connecticut, Vol. 6, from the Year 1866-1870”, 1872, page 977

1923-1969 Werman's Shoe Factory

*Place cursor over images to magnify

The C.B. Rogers & Company sold out to the American Wood Working Machine Company in 1897. The former C.B. Rogers building, near present-day Norwich Police Station, became the new home for a new company, A. Werman & Sons, Incorporated.

This successful shoe manufacturing company, founded by Abraham Werman in 1918 in Brooklyn, New York expanded its ability to produce high quality shoes and sandals in 1923, when it opened its new facility in Norwich. Abraham, his sons, and later his grandsons operated the company in Norwich for many years. The company employed thousands people in Norwich from 1923-1969.

A. Werman & Sons, Inc. was a fine example of a thriving family business throughout its tenure. Abraham oversaw the Brooklyn, New York factory, while two of his sons, Gustave and Jacob, managed the Norwich plant. Later, in 1946, Jacob’s son, Stanley was given the task of opening and running a third factory in Marietta, Pennsylvania.

The shoe manufacturing industry was thriving in New England in the 1930s. The New England Shoe and Leather Association held its prestigious 20th Annual Boston Shoe Fair, held June 5-8, at Boston’s Parker House and Hotel Statler. The fair featured more than 600 shoe manufactures, including Norwich’s A. Werman & Sons.

Not only did the Werman family supply the Norwich community with many jobs, it also advanced the science of shoe manufacturing. The 1965 patent, shown on the left, was submitted by two of Abraham Werner’s grandsons, David and Martin. These Norwich residents devised a novel method of “molded shoe construction.”

According to the patent description: “This invention may be briefly described as an improved essentially monolithic construction for stitch down or other extension edge types of shoes which includes, in its broad aspects, a molded in place outsole having an integral peripheral edge portion thereof disposed in overlying relation with and mechanically interlinked to said extension edge and methods for fabricating the same.”

*Place cursor over image to magnify

In 1966 Martin S. Werman also invented an apparatus for the heat activation of adhesives on shoe components. A discussion of the Werman family patents is provided at: Werman’s Shoe Patents .

Acknowledgements

“Abraham Werman (1873-1955)” Find A Grave

“Werman’s Shoe Factory,” Norwich Ct. Pictures, USA

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Werman” in the SEARCH box.

1930-1972 Thames belting Company

*Place cursor over image to magnify

Ulmer Leather Co. - 1938

The Thames Belting Company was incorporated on August 22, 1930 by L.R. Cochran. In 1938 Cochran, G.M. Schelin, J.F. Wilde and L.N. Lanoie added to their company when they bought the former Ulmer Leather Company. Their facility was located at the end of Forest Street in Norwich.

The photo on the left is a copy of the 1930 Thames Belting Co. business card. It shows that the company produced several types of belts, including: Regular oak, Waterproof Oak, Chrome and Retan, Combination Oak – Chrome, and Fabric Backed Oak or Chrome. (FYI: the term “Chrome Retan” is leather that has been chrome-tanned all the way through and subsequently treated with a combination of vegetable-based or synthetic tanning.) The company also refurbished used belts.

The photo on the right shows the building used by the Thames Belting Company shortly before it was purchased in 1938. The 3-story building was 175 long x 42 feet wide and could process 5,000 pounds of finished belting in a single week.

The company made commercial leather belts that powered machines.

By 1962 the Thames Belting Co. shared a large portion of their building with the Van Tassel Leather Company. Van Tassel used their portion of the building as a warehouse. The Van Tassel warehouse was destroyed and four firefighters were killed due to an explosion on April 3, 1962. The consequences of the fatal Van Tassel Fire are still felt by Norwich today.

After the diastrous fire, the Thames Belting Company moved their production facility to Yantic, where it stayed in business for approximately ten more years.

Acknowledgements

“60 Years Later, Memories of Fatal Van Tassel Warehouse Fire Remain Vivid in Norwich,” by John Shishmanian

Norwich Ct.Pictures, USA – Facebook website

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Thames Belting” in the SEARCH box.