Choose A Manufacturer

Yantic Manufacturing Sites Overview

There were two manufacturing sites located in the present-day neighborhood of Yantic. The oldest site was located near present-day Yantic Flats Road and the Yantic River. The Elijah Backus family operated an iron forge there during the colonial era. They manufactured blooming and bar iron for anchors, mills and cannon carriages.

The other site, on Yantic Road near the present-day Yantic Volunteer Fire Department, became the home of the Yantic Woolen Mills. Manufacturing began at the site in the early 1800s in the form of a mill dam, a sawmill, a grist mill, and a carding facility. The group of enterprises gradually gathered into a manufacturing center. These facilities were purchased over the period of 1818 to 1822 by John and George Tisdale. They added a factory and a stone dwelling-house to the premises, and began the manufacture of cotton cloth. The Tisdales represented Robert R. Baker, a native of Scotland, who had spent some time in Norwich, and seems to have formed a desire to invest his capital in Norwich. However, in the late 1820s Mr. Baker disappeared and his fate was never ascertained.

In 1827 Captain Erastus Williams acquired the property. After changing the name of the area from West Farm to Yantic, he converted the cotton mill to a woolen mill.

Acknowledgements

New England Yard & Pattern

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” pp 606, 615

175?-179? Elijah Backus Iron Works

Elijah Backus (1726-1798) operated an iron works in Norwich during the colonial era. Elijah was a direct descendant of two of the 35 original founders of Norwich, William Backus Sr. and Lt. William Backus Jr.

Backus operated one of the first forges in New London County. He manufactured blooming and bar iron for anchors, mills, and other users. During the Revolutionary War period, he cast cannons, mortars, and horseshoes for the Continental Army and anchors for privateers.

The following is an excerpt from Info Source 1:

“The Backus Iron Works, with its lurid fires was quite an institution in its day, and quite an important factor in the growth and development of the country and its times. The iron works made bar iron, tires for wheels, plow irons, spindles and cranks for mills, sawmill saws; all kind of farming tools, such as hoes, axes, scythes; nautical needs such as spindles for buoys, anchors – about everything that was made of iron – and largely supplied the wants of that day. Nails were quite important at that time, all were hammered out by hand for all the purposes of domestic use, no nails being cut at that time.

Its customers were heard from in quite distant parts of the country, even from the new “Northwest Territory”. The iron work for the first saw and grist mill erected in the Northwest Territory was made at these works, and transported by land and water, to and over the Allegheny mountains on pack horses, to the then far-distant land of hope – Marietta, Ohio, in 1789.

The iron was made at the melting fire, which was kept in blast by two huge bellows run by water power, and required a strong draft of air. The old structure was a large building having three tall chimneys, the roof partly covered with sheet iron as a protection from fire, nd covering three forges, two water wheels, stamper run by water for pounding iron ore, the big shaft and the big hammer. To conduct the process of melting and hammering out into all required shapes required a skilled and strong man.

The Backus Iron Works was important for the only source for these products from within miles around. At Backus Iron Works, they hammered out tools for the farmers and the artisan – directly and indirectly helping materially to hammer out American Independence.”

Acknowledgements

Geni.com

“Woodbridge and Backus families business records, 1754-1890 (inclusive),” Harvard Library

“History of Norwich, Connecticut: From Its Possession From the Indians, to the Year 1866,” pp 606,

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Elijah Backus” in the SEARCH box.

1827-1865 First Yantic Woolen Mill

When Captain Erastus Williams acquired the property in 1827, known as West Farm, he renamed it to Yantic, meaning “Little River”. Prior to that time there had been some manufacturing at the site which included a grist mill, a saw mill, a carding mill operation and a short-lived cotton mill.

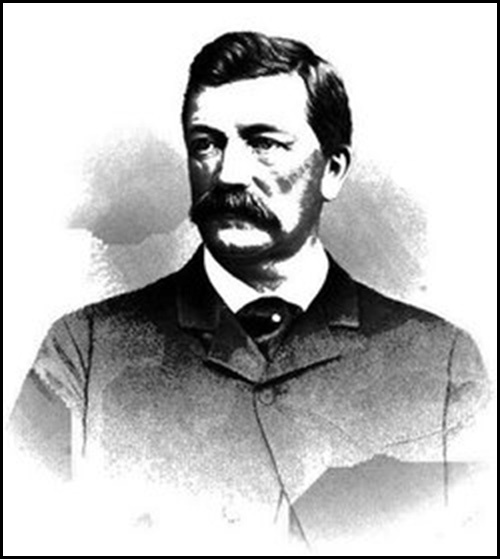

Williams was a wealthy former sea captain who retired at an early age to live in Norwich, enlarged the cotton mill and converted it to the production of woolens. Williams later served as Mayor of Norwich from 1853 to 1855.

The photo shows the company store.

*Place cursor over photo to magnify image

The mill produced flannel, a high quality, napped carriage-cloth. Early views of his mill show it to be a long 3 ½-story brick structure, with a clerestory roof and a small belfry at one end surmounted by a weathervane in the shape of a sheep, undoubtedly intended to honor the source of merino wool. At least one wing was built of stone. It was a relatively large woolen mill for its day, employing 75 males and 35 females in 1860.

Captain Williams was assisted in running the mill by his son, E. Winslow Williams, who assumed sole control following a disastrous fire in 1865. Within three months of the fire, E. Winslow Williams laid the cornerstone for a new, larger main mill. Refer to next placemark for details.

Acknowledgements

National Park Service

New England Yarn & Pattern

Norwich Ct. Pictures, USA

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “First Yantic Woolen Mill” in the SEARCH box.

1865-1989 Second Yantic Woolen Mill

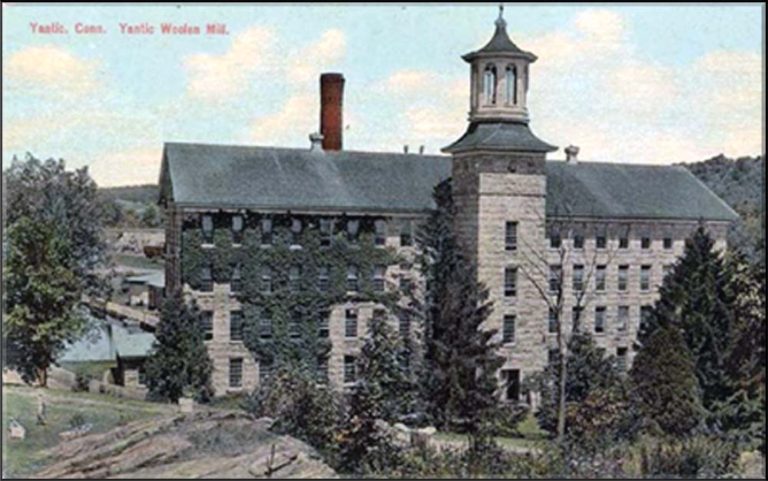

The second Yantic Woolen Mill is part of a mill complex located in the Yantic neighborhood of Norwich. Built in 1865, the mill is a well-preserved example of mid-19th century textile mill architecture, and was the major economic force in the village of Yantic. The mill was added to the National Register of Historic Places 1996.

In 1865 a fire destroyed the first Yantic Woolen Mill. However, soon after the fire E. Winslow Williams, Captain Erastus Williams‘ son, assumed sole control of the company. Within three months of the fire, he laid the cornerstone for a new, larger main mill. The new mill was very successful. About 1877 the mill and the complete manufacturing enterprise was incorporated as a stock company, the Yantic Woolen Company, with E. Winslow Williams at its helm.

Originally, the mill produced flannel, a high-quality carriage-cloth woven fabric with a short, stiff nap. The cloth was dyed and finished at the mill and was sold through Boston and New York merchants. In both 1887 and 1892 the mill was enlarged to meet demand when new wings were added.

By 1900, the firm had transitioned into the production of woolen and worsted fabrics for suits and outerwear. Buoyed by rising demand for the mill’s flannel, the number of looms rose from 32 in 1870 to 88 in 1900. The additional looms allowed the mill’s production to grow from 1,000,000 yards to 2,250,000 yards a year. At that point-in-time there were approximately 125 mill employees.

The mill’s main building is a large 4½-story granite structure with a five-story square tower at its center, (shown on the postcard pictured above). The tower was originally capped by an octagonal belfry. The main mill is connected to a series of smaller stone buildings. The mill was powered by water delivered from the Yantic river via a stone headrace that ran from a dam about ½ mile to the northwest.

After his death in 1888, E. Winslow Williams was succeeded by his son Winslow Tracy Williams.

In the 20th century the Yantic Woolen Company entered a period in which numerous successive changes occurred in ownership and operation. In 1913 the company was placed in receivership, and Winslow Tracy Williams reorganized the company as the Admore Woolen Company.

In 1916 the company expanded its production when it built a new, more modern plant in the Thamesville area of Norwich. The Thamesville mill, conveniently located adjacent to both the Thames river and the Central Vermont Railway, had the ability to easily transport raw materials and finished products both into and out of the mill.

During World War I, the Yantic mill ran two shifts producing blankets and overcoat cloth for the government. Soon thereafter Williams sold the mill to Louis and Ira Kaplan, who operated it as the Liberty Woolen Company.

In 1921 the Yantic Woolen Company mill was acquired by the American Woolen Company. They idled the Yantic mill after consolidating production at the Thamesville mill. During the Depression, (1929-1939), the Yantic mill was operated by four different entities and was idle part of the time. After a brief resurgence during World War II, (1939-1945), weaving was suspended and it became solely a spinning mill, providing yarn for other mills to weave.

In 1968 the Yantic mill was acquired by Hale Manufacturing Company of Putnam, Connecticut. The Hale managers could modify the plant’s methods and machinery to process rayon and other synthetics such as automobile upholstery fabric. This modification extended the life of the old mill for another two decades. By the time production ceased in 1989, the entire United States textile industry had become enmeshed in a global economy that no longer favored the small scale and ancient machinery that characterized mills such as Yantic.

Today the Yantic Woolen Company Mill stands as a reminder of the central role that textiles played in the development of eastern Connecticut.

In December 2018 a renovation of mill building was approved by the Norwich Historic Commission. The plan includes converting the building to a high-end 151 room hotel.

Acknowledgements

National Park Service

New England Yarn & Pattern

New England Yarn & Pattern

National Park Service

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Second Yantic Woolen Mill” in the SEARCH box.