Choose A Manufacturer

1866-1972 Ponemah Mills

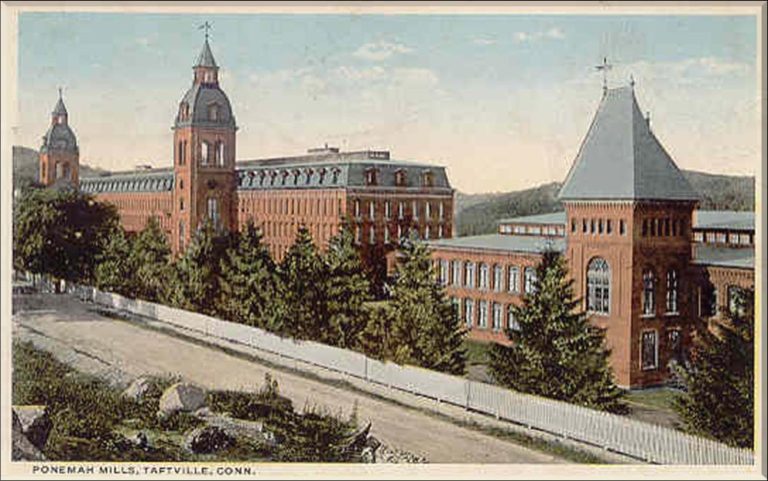

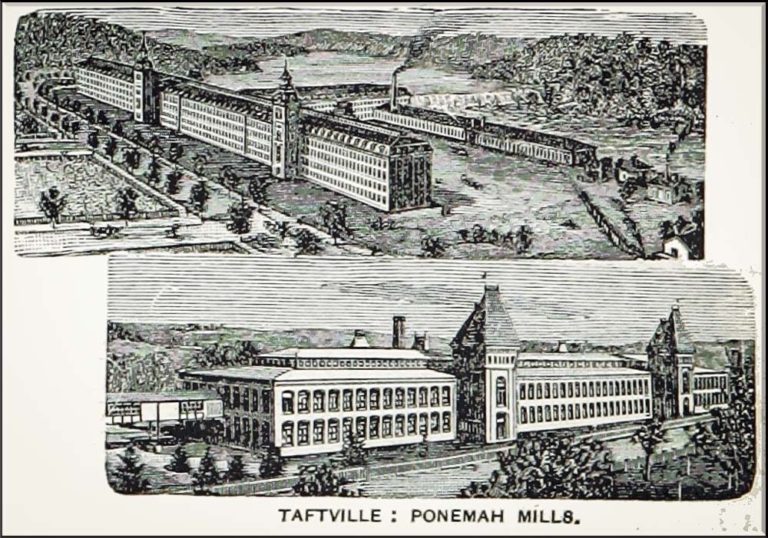

Ponemah Mills was one of of the largest textile mills in the United States for many years. The large original buildings were started in April 1866 and began operation November 16th, 1871. Additional mills were built in 1884 and 1902, and the large weave shed was added in 1910.

Edward P. Taft first purchased a mill privilege and 600 acres of land lying on both sides of the Shetucket River, four miles above Norwich in 1865. Shortly thereafter in April 1866 construction of the Ponemah Cotton Mill began. The original corporators were Edward P. Taft, James S. Atwood, Cyrus Taft and Moses Pierce. Unfortunately, these original owners were not able complete the project.

However, in December 1869 the Orray Taft Manufacturing Co. was incorporated with several, new major investors, (John Fox Slater , Lorenzo Blackstone, et. al.). The construction resumed and when the mill was completed, the name of the company was changed to Ponemah Mills and the mill began operation in 1871.

The name “Ponemah” was taken from Henry Wadsworth Longfellow’s poem, Song of Hiawatha, and was said to mean “our hope”.

The mill owners built a village to house the workers, naming it Taftville after the principal investors. The main street of the new village was named Providence Street.

The first mill was 750 feet long and 74 feet wide

Ponemah Mills spun and wove imported Egyptian cotton into very high quality cloth for the luxury trade. It was the first mill in the United States to use Egyptian cotton. The cotton’s fine texture produced a luxurious, highly coveted cloth with an extraordinarily high thread-count.

A bitter strike in 1875, led to the eviction of mill workers who were mostly comprised of Irish Americans. New workers were recruited from French Canada. Taftville became noted as a French Canadian community.

Major expansions of the mill were made in 1884, 1902, and 1910. It was one of the largest textile mills in the United States for many years. At its peak, the Ponemah Mills employed 1600 workers and produced over 20 million yards of cloth a year. They boasted that a pound of cotton could be spun into a single strand of yarn 100 miles long. In the 20th century, the mill successfully converted to the production of synthetic fabrics.

In 1924 Ponemah Mills, boasting its 4,000 looms and huge number of weavers, were at a historic level of production.

The mill was closed in 1972, one of the last great New England mill to shut down.

Acknowledgements

Historic Structures

“Ponemah Mills, HABS No. CONN-242,” 1960, by Osmund R. Overby

Public Domain

Jack Delano, 1940, from the Library of Congress archives

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “Ponemah Mills” in the SEARCH box.

1898-1938 J.B. Martin Velvet Mill

The J.B. Martin Velvet Mill - circa 1905

In 1832, Jean Baptiste Martin founded the J.B. Martin Company, and produced velvet near Lyon, France. In 1898, Martin opened a new plant in Taftville which manufactured both velvet and silk. By the year 1909 the Taftville mill annually produced more than 1,000,000 yards of velvet. The company employed 400 people in the year 1914.

The company had a major breakthrough in 1928 when William H. Stebbins of Norwich, and his partner, Chester L. Hussey were awarded a United States Patent for the design of a bidirectional loom.

Unfortunately, the Hurricane of 1938 struct the mill hard and the J.B. Martin Company was forced to close the Taftville velvet mill. However, the company survived and by the late 1950s, production (weaving, dyeing, and finishing) was moved to Leesville, South Carolina.

The JB Martin Company is still in operation today. It services worldwide decorative wholesalers, furniture manufacturers, and contract market (theater curtains, auditorium seating). The company offers piece dyed, yarn dyed, plain, embossed, crushed, and printed velvets. Their products incorporate a wide variety of fibers, including cotton, rayon, mohair, linen, acrylic, polyester and outdoor solution dyed acrylic.

1946-1988 American Thermos Co. - Taftville Plant

After the J.B. Martin Co. closed its doors in Taftville in 1938, the Velvet Mill building stood empty for a few years. In April 1942, the Hamilton Standard Company reopened the facility and began making controllable-counterweight propellers for light transport planes and airplane trainers. These propellers were used in support of United States Army Air Forces during World War II . By the end of the war more propellers were not needed and the building was shut down again.

In 1946 the building was put into use again by the American Thermos Company. The Laurel Hill plant was at full capacity and needed additional manufacturing space. The production process was split into two parts. The vacuum-glass bottle production was done at the Laurel Hill plant and the metal fabrication was accomplished in the Taftville facility.

EVERYBODY WINS

The former velvet mill was used as a set in the 1990 movie “Everybody Wins“, starring Nick Nolte and Debra Winger. The film was shot primarily in Norwich. Some of the other featured locations included: Norwich City Hall, the Norwich Free Academy, the Harbor, Park Church, Canterbury Turnpike, Washington Street and Washington Street Extension, Downtown Norwich, as well as many identifiable homes. The concluding scene features a stately white house on top of a hill off Washington Street Extension.

After the movie was produced a couple of developers began to convert the old velvet mill into condominiums, but the condo market collapsed and the project failed. The old velvet building was demolished and is now the site of a school bus parking lot.

Acknowledgements

“The Rose of New England – Norwich, Ct Celebrates the 250th Anniversary of Its Founding,” 1909, p 438

National Register of Historic Places Registration Form

The complete list of sources may be found by clicking the “Bibliography” button, and, then typing “velvet” or “Thermos” or “Nolte” or “propeller” in the SEARCH box.